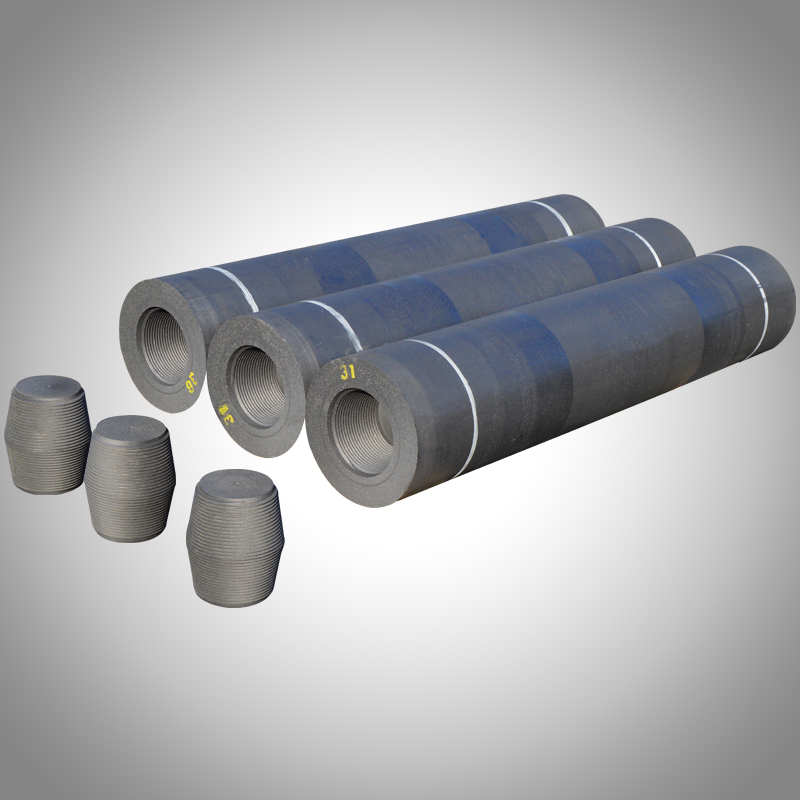

graphite electrode and nipple

Graphite electrodes are presently the only products available that have the high levels of electrical conductivity and the capability of sustaining the extremely high levels of heat generated in this demanding environment. They are used to refine steel in ladle furnaces and in other smelting processes. These act as conductors of electricity in the furnace, generating sufficient heat to melt scrap metal, iron ore or other raw materials used to produce steel or other metals. In a typical furnace using alternating current and operating at a typical number of production cycles per day, one of the nine electrodes is fully consumed (requiring the addition of a new electrode), on average, every eight to ten operating hours. The actual rate of consumption and addition of electrodes for a particular furnace depends primarily on the efficiency and productivity of the furnace.

Size/Weight Chart

| Name | Electrode diameter | Electrode length | Electrode weight (reference value) | |||

| Diameter x length | Maximum | Minimum | Maximum | Minimum | Electrode product weight (excluding nipple) | |

| inch | mm | mm | mm | mm | mm | kg |

| 14×60 | 350×1500 | 357 | 352 | 1550 | 1400 | 253 |

| 14×72 | 350×1800 | 1875 | 1700 | 304 | ||

| 14×96 | 350×2400 | 2475 | 2275 | 406 | ||

| 16×60 | 400×1500 | 409 | 403 | 1550 | 1400 | 334 |

| 16×72 | 400×1800 | 1875 | 1700 | 395 | ||

| 16×96 | 400×2400 | 2475 | 2275 | 532 | ||

| 18×72 | 450×1800 | 460 | 454 | 1875 | 1700 | 496 |

| 18×96 | 450×2400 | 2475 | 2275 | 665 | ||

| 18×110 | 450×2700 | 2850 | 2550 | 766 | ||

| 20×72 | 500×1800 | 511 | 505 | 1875 | 1700 | 614 |

| 20×84 | 500×2100 | 2175 | 1975 | 715 | ||

| 20×96 | 500×2400 | 2475 | 2275 | 824 | ||

| 20×110 | 500×2700 | 2850 | 2550 | 927 | ||

| 22×84 | 550×2100 | 562 | 556 | 2175 | 1975 | 873 |

| 22×96 | 550×2400 | 2475 | 2275 | 995 | ||

| 24×84 | 600×2100 | 613 | 607 | 2175 | 1975 | 1040 |

| 24×96 | 600×2400 | 2475 | 2275 | 1190 | ||

| 24×110 | 600×2700 | 2850 | 2550 | 1340 | ||

| 26×110 | 650×2700 | 663 | 657 | 2850 | 2550 | 1580 |

| 28×110 | 700×2700 | 714 | 708 | 2850 | 2550 | 1830 |

| 30×110 | 750×2700 | 765 | 759 | 2850 | 2550 | 2060 |

Guide to Graphite Electrodes

| Unit | AC Furnace | DC Furnace | |||

| 350~450mm | 500~700mm | 550~800mm | |||

| 14"~18" | 20"~28" | 22"~30" | |||

| Features | RP | HP/UHP | UHP | UHP | |

| Bulk density | g/cm3 | 1.58~1.70 | 1.65~1.76 | 1.66~1.74 | 1.68~1.75 |

| Specific resistance | μΩm | 6.0~8.5 | 4.5~6.5 | 4.5~6.5 | 4.2~5.5 |

| Young's modulus | kN/mm2 | 8~12 | 11~16 | 9~14 | 9~13 |

| GPa | 8~12 | 11~16 | 9~14 | 9~13 | |

| kgf/mm2 | 800~1,200 | 1,100~1,650 | 950~1,400 | 900~1,300 | |

| Bending strength | N/cm2 | 1,000~1,400 | 1,200~1,800 | 1,000~1,500 | 1,000~1,500 |

| MPa | 10~14 | 12~18 | 10~15 | 10~15 | |

| kgf/cm2 | 100~140 | 120~180 | 100~150 | 100~150 | |

| Thermal expansion coefficient | ×10-6/゚C | 0.8~1.5 | 0.8~1.5 | 0.5~1.0 | 0.5~0.9 |

| (R.T. to 400°C) | ×10-6/゚F | 0.4~0.8 | 0.4~0.8 | 0.3~0.6 | 0.3~0.5 |

| True density | g/cm3 | 2.20~2.23 | 2.20~2.23 | 2.20~2.23 | 2.20~2.23 |

| Total porosity | % | 23~29 | 20~26 | 21~26 | 20~25 |

| Ash content | % | Less than 0.3 | Less than 0.3 | Less than 0.3 | Less than 0.3 |